FROM NATURE

made with fruit peel

AVOIDING PLASTIC

We love nature

Hold your Smart Phone in position

for reading recipes, watching videos

or good old chatting.

Using our 3D Printed Smart Phone Holders

made with fruit peel. Avoiding Plastic.

Available in

Orange - Lemon (Yellow) - Lime (Green)

also available in Coffee - made from used coffee grounds from the Coffee Shops of Milan

Welcome to Milan

Milan is home to Krill Design. Milan is also home to some iconic yellow trams. The tram drivers are very mindful of the other road users ...and our Director Chris, when he took this shot!

A bit of background about

Krill Design

who make these products

Krill Design are based in Milan, Italy

Early Research

& Vision

The three founders of Krill Design met while working at Milan Polytechnic, one of Italy's leading universities. They were sure that something could be done with fruit peel to make it useful as a new material for a sustainable world. They set about doing some early research thinking about potato peels and egg shells before focussing their efforts on re-using orange peels.

The Krill Design Vision

FOOD WASTE AS A RESOURCE

The consideration of the founders was quite simple. There are already several supply chains that intercept and recover waste from the production of paper, glass and plastic. But for organic by-products of the food chain, there are no virtuous solutions.

They converted this problem into an opportunity, experimenting with the creation of innovative materials, which when combined with 3D printing, enable a successful and environmentally friendly production process.

View our products

First customer - Autogrill WAS ORANGE

Having formed Krill Design, one of their early customers was Autogrill. Autogrill is a large Italian company who run over 3000 service stations on the Italian motorway network. Autogrill have been very advanced in their adoption of sustainable ideas and worked with many different partners and suppliers. They asked Krill Design to work on a solution for all the orange peels that were being discarded from all the freshly pressed orange juice that they serve to their customers.

Autogrill press 28 million oranges per year!

The project with Krill Design aims to save 85 tonnes of CO2.

Some of the products made for Autogrill using the orange peel include baskets for the sugar on the espresso counters in their coffee shops. These have been branded internally as:

"WAS ORANGE"

Working with Sanpellegrino

The well known Italian drinks maker Sanpellegrino has not only become a supplier to Krill Design of their fruit peels after the juice is squeezed, but they have also had branded products 3D printed for them by Krill Design with Rekrill® for their own brand promotional purposes. These include ice buckets, serving trays and even a lamp in the form of an orange segment. These product designs were all created by Italian Designer Seletti.

All products are

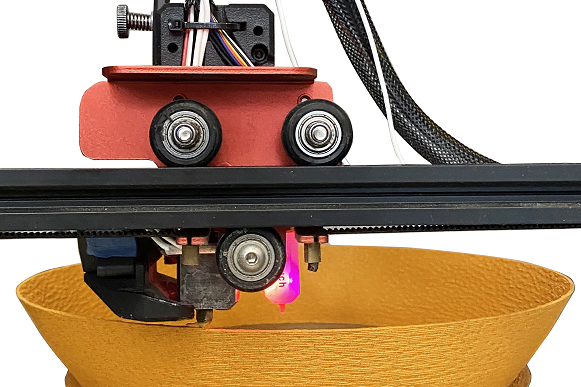

3D printed

The process

First the peels and pips are dried. Then they are made into pellets. These pellets are then converted into a filament ready to be used in a 3D printer. This filament is known as Rekrill®.

Then, when a product design is ready, it can be 3D printed with the Rekrill® filament, avoiding plastic.

Avoiding Plastic and reducing CO2

Not only is the Rekrill® material a fabulous re-use of fruit peel which would otherwise be discarded but when used for new products like the Smart Phone holders, it avoids the use of plastic and reduces the amount of CO2 used.

Krill Design have estimated that a Smart Phone holder made with Rekrill® has an 87% lower CO2 footprint than the equivalent product made with plastic.

Awards

Krill Design have won numerous awards. One of the most significant was in 2022 they won the Best small company in the Circular Economy in Italy award.

They are also a certified B-Corp.

Video interview with

Yack di Maio

Co-founder of Krill Design

In this 2 minute video, Yack explains the purpose of Rekrill®